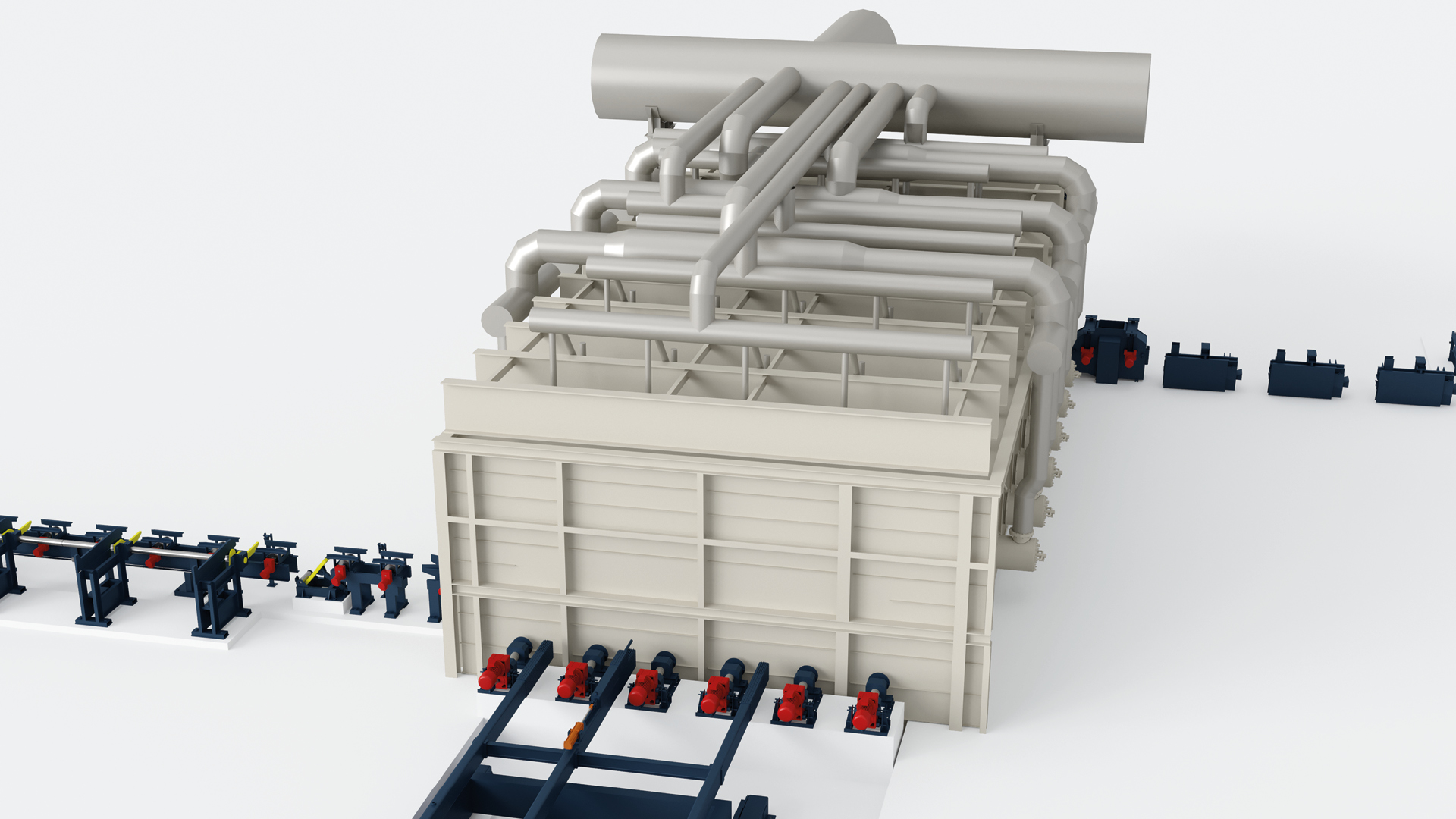

REHEATING FURNACE

Metech STG can provide a full set of reheating furnaces and heat-treatment furnaces with all type of arrangements for metallurgical plants. It is specialized in the design and construction of the whole equipment involved in the combustion process, in temperature control technology and in the control of the combustion ratio.

Metech STG supplies taylor-made solutions for an integrated connection between the continuous caster, the reheating furnace and the rolling mill, in order to perform the hot charging process of the as-cast billets from the CCM into the RHF, thus allowing energy savings in the range of 30-50% if compared to the traditional cold charging.

Main RHF focuses:

- Modern profile

- No dangerous points as separation noses

- Low fuel consumption

- Good product temperature uniformity

- Reduced product bending

- Good product heating curve

- Minimized scale loss

- Reliability during exercise

- Flexibility both with cold and hot product charge

- Low maintenance

FURNACE TYPES pusher type

walking hearth

walking beams

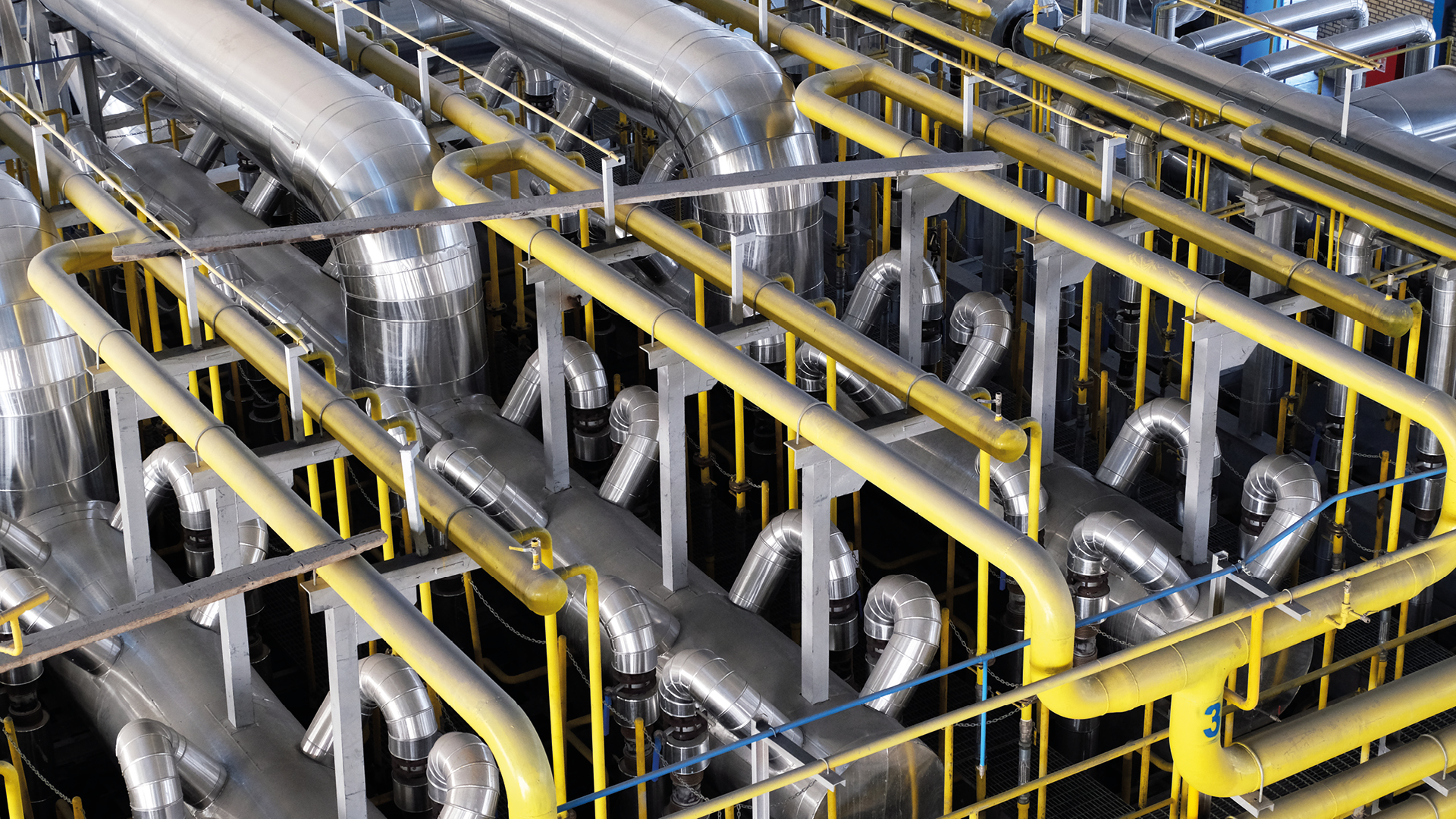

BURNERS unitary thermal power between 100,000 and 5,000,000 Kcal/h or more

BURNER FEEDING Natural gas / LPG / Oil / Gasoil / Crude oil / Oil coming from tyre pyrolysis / Coke oven gas / Blast furnace gas / Syngas