MEDIUM SECTION ROLLING MILL

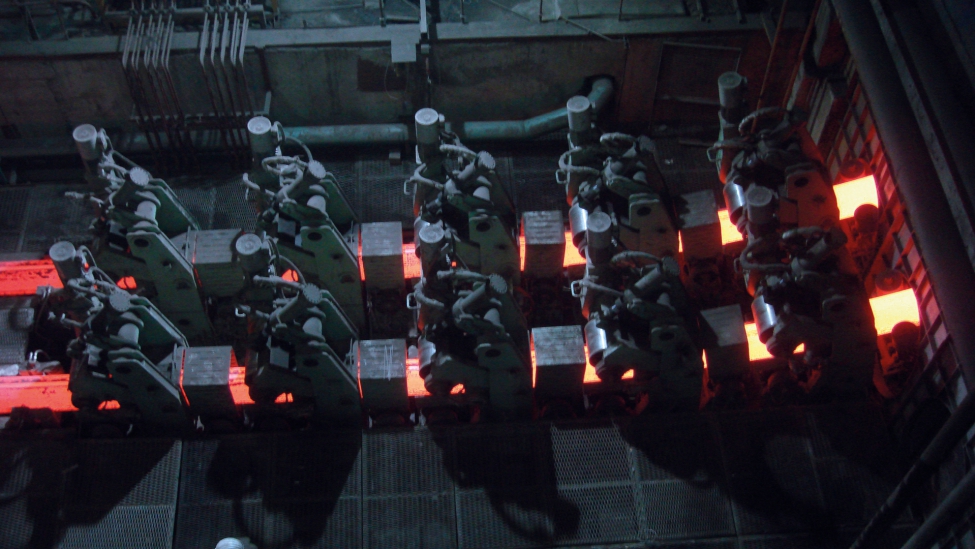

The experienced process engineers of Metech STG dedicated Rolling Mill team devise medium sections RM for a wide product range. Billets or beam blanks, coming from hot or cold charging, enter the stand mill area which consists of Metech STG robust housing-less rolling stands with alternated horizontal and vertical stands in the roughing mill; horizontal, vertical or universal stands in the intermediate mill; horizontal and universal stands in the finishing mill, according to roll pass design.

After its stay on the cooling bed, the product enters the finishing area for final processing through our sturdy, fully equipped Multistrand Straightening Machine.

In the end, the product goes through the last part of the finishing area, which is composed by cold saws for final length cutting, stacking unit, tying or strapping machine, discharging unit, weighing machine and collecting station, and is finally moved to the packing and storage area by crane with magnets.

Product range

ANGLES from 80x80 to 200x200 mm

CHANNELS UPN from 80 to 280 mm

IPE BEAMS from 80 to 400 mm

HE BEAMS from 80 to 240 mm

STARTING MATERIAL Billets up to 200 mm

Beam blanks up to 430 x 300

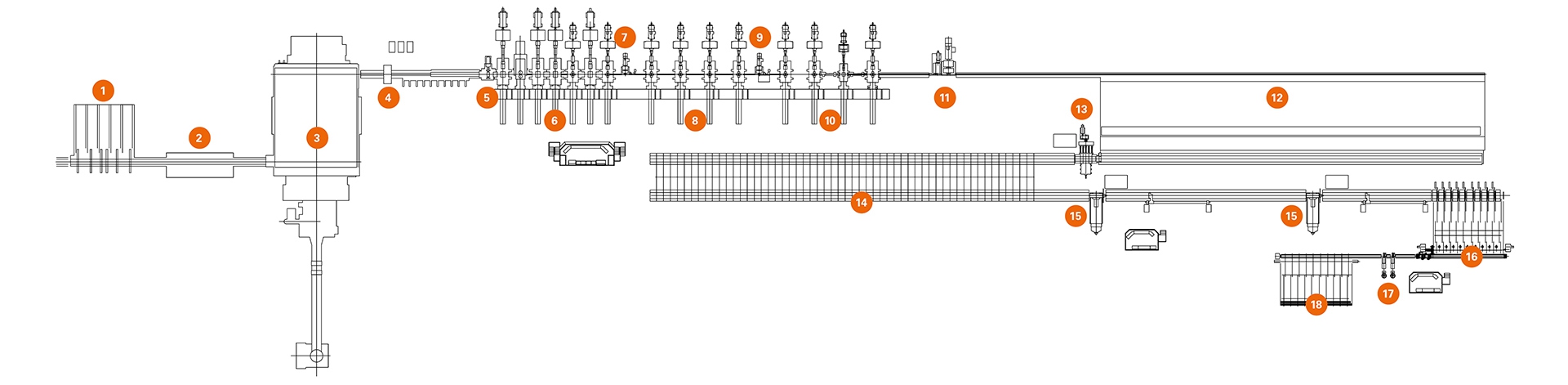

1. Hot/Cold Charge

2. Weighing System

3. Walking Beam Reheating Furnace

4. Descaler

5. Pinch Roll

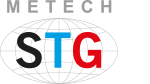

6. Roughing Mill (Horizontal, Vertical and Universal Stand)

7. Crop Shear

8. Intermediate Mill (Universal Stand)

9. Crop Shear

10. Finishing Mill (Universal and Horizontal Stand)

11. Dividing Shear

12. Cooling Bed

13. Straightening Machine

14. Chain Transfer

15. Disk Saw

16. Stacking Station

17. Tying Machine

18. Collecting Station